Understanding what materials can and cannot do in various industries is crucial. Knowing how materials behave under specific conditions is essential for decision-making in construction, manufacturing, product design, and various other applications. That’s where tensile testing machines come in. These devices explore a material’s properties and provide vital insights into its strength and durability. This post will discuss what tensile testing machines reveal about material strength and why that information is important.

Why Tensile Testing?

The tensile test is a basic measure of a material’s behaviour under stress. A tensile tester machine applies tension to a specimen in a controlled manner and measures its stretching response. This process highlights important properties such as tensile strength, elongation, and elasticity. These characteristics inform how materials will perform in the field, ensuring they are safe and effective for their intended applications.

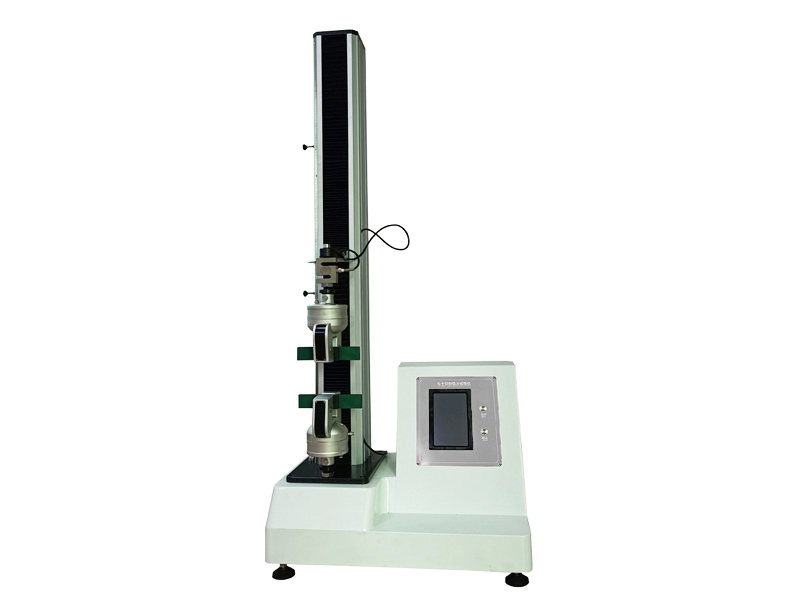

Parts of Tensile Testers

A typical tensile testing machine contains several essential components. A set of grips or clamps holds the material sample in place to prevent movement during the test. The machine applies force through a load cell, which accurately measures the applied tension. Tension is generated by the movement of the machine’s crosshead, which stretches the material until it fails. This setup allows for precise measurement of material stress.

Important Parameters in Tensile Testing

Tensile testing produces a wide range of measurements, each offering insights into material behaviour. One key measurement is tensile strength, which indicates the maximum stress a material can withstand before failure. Elongation is another critical parameter, representing how much a material can stretch before breaking, as an indicator of ductility. The modulus of elasticity shows how much a material deforms under stress and reflects stiffness or flexibility. This data helps engineers and designers select appropriate materials for specific applications.

Use Cases in Various Sectors

Tensile testing data is vital for refining products and processes across industries. In construction, it determines how much load and stress steel or concrete can handle. The automotive industry uses this data to choose materials that can withstand impacts and enhance vehicle safety. In aerospace, engineers rely on tensile testing to ensure materials can endure the extreme flight conditions. These examples demonstrate the wide-ranging importance of tensile testing across multiple sectors.

Technology in Testing

Technology has redefined how tensile testing is conducted. Modern machines feature digital interfaces that allow real-time data visualisation and analytics. Automation reduces human error and increases consistency. Advanced software helps interpret the results, offering profound insight into material behaviour. These innovations enhance both precision and efficiency, benefiting industries globally.

Challenges in Tensile Testing

Despite its advantages, tensile testing has some limitations. Accurate sample preparation is essential, as inconsistencies can produce unreliable results. Choosing the right grips and fixtures for different materials also requires careful consideration. Additionally, interpreting test data demands skilled professionals because many variables affect material performance. Addressing these challenges ensures dependable, high-quality results.

Material Testing in the Future

The future of tensile testing looks promising. Integrating artificial intelligence and predictive data analysis will enable smarter, more accurate decision-making. As new materials are developed, testing methods will evolve to understand their properties. This continual advancement will ensure that industries get the most out of their materials.

Conclusion

A tensile testing machine does more than just measure material properties; it offers deep insight into material strength. These tests help industries design safer, more efficient products and structures. As technology advances, tensile testing will continue to be essential for engineers, designers, and researchers. It bridges the gap between theory and real-world application, driving innovation and development.

0 Comments